Manufacturing & Engineering

Whether you’re looking to monitor and maintain a safe plant floor or calibrate your equipment to ensure precision and accuracy, Dillon’s range of load limit devices and force gauges are up for the job

Products Used in Manufacturing & Engineering

Load Limit

Dillon’s Load Limit devices offer a clamp-on or in-line solution to hoist overload and line slack.

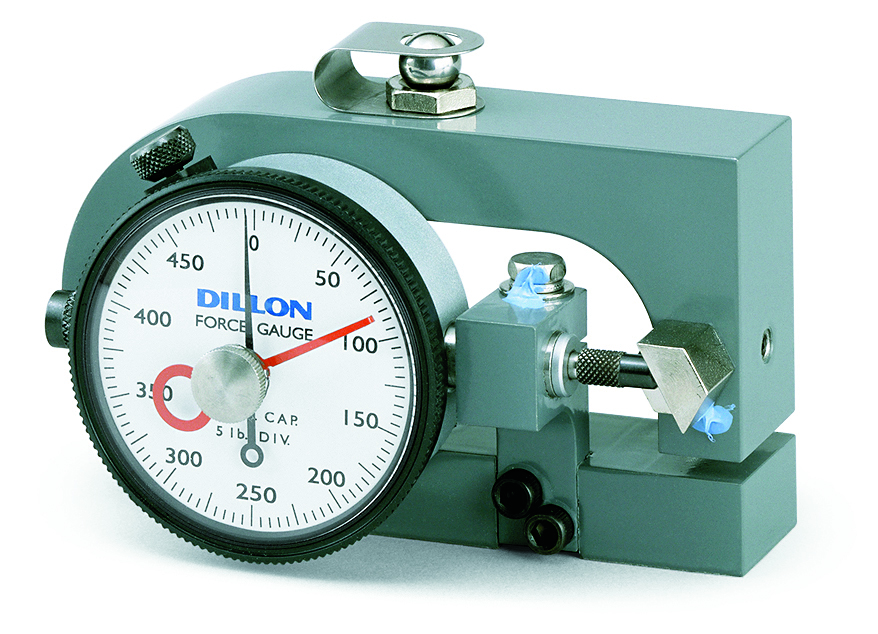

FI-521

The FI-521 is a durable, high featured force indicator with three load cell memory.

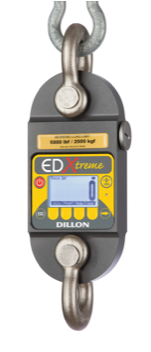

EDXtreme Dynamometer

The EDXtreme exemplifies the trademark precision and rugged construction of Dillon Dynamometers.

ABOUT DILLON IN Manufacturing & Engineering

Most manufacturing floors vary greatly in what they do and how they operate, but they all have one thing in common that Dillon helps make possible… safety.

You can’t visit a plant without hearing about safety and watching a video on it. But no matter how safe you are, accidents can happen. Dillon load limit devices prevent overload and line slack on your hoists making the accidental operator error a training opportunity instead of a line shutdown, or worse.